To calculate the proper length of a heated hose assembly, you need to:

- Verify that the installation is properly designed

- Do not torque the hose

- Do not overbend the hose

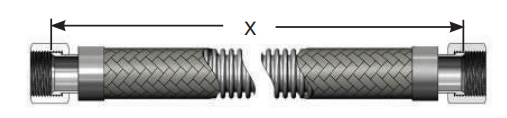

- Do not compress the hose

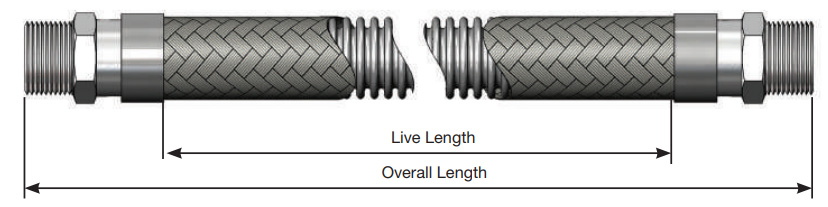

- Calculate the live length of the assembly – The live length of the assembly is the amount of active (flexible) hose in an assembly; that is, the hose between the braid collars.

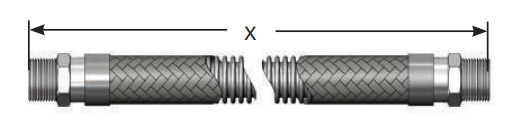

- Calculate the overall length of the assembly – Overall length is equal to the live length plus the lengths of the braid collars and fittings. When adding fitting lengths, be aware that the points from which measurements should be taken vary for different fitting types. When calculating overall length for assemblies with threaded fittings, remember to account for the length of thread that is lost by threading into the mating connection.

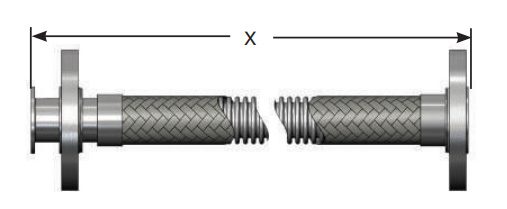

| JIC/SAE-type fittings are measured from the seat of the fitting. |

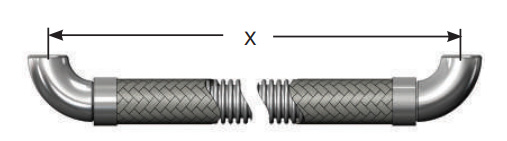

| Elbows and other fittings with a radius are measured from the centerline of the fitting. |

| Flanges are measured from the flange face or from the face of the stub end if one is used. |

| Threaded fittings are measured to the end of the fitting. |

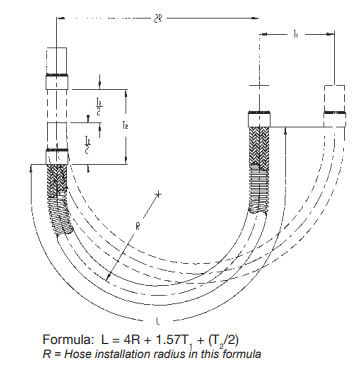

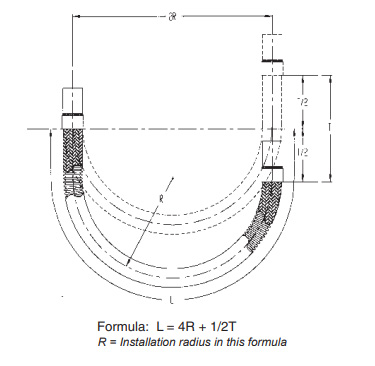

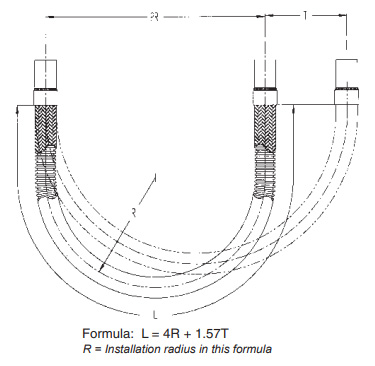

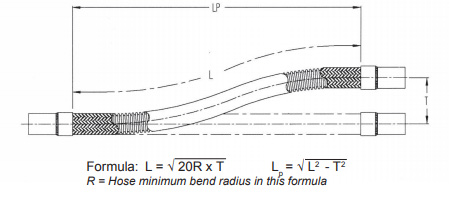

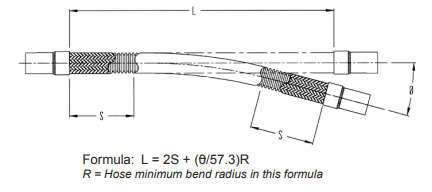

For the following formulas:

L = Live length of hose (inches)

T = Travel (inches)

S = Hose outside diameter (see product data pages)

Verify that the installed radius is greater than the stated Minimum Bend Radius for the hose at the required working pressure.

Verify that the centerline of the hose remains in the same plane during cycling to prevent twisting the assembly.

CONSTANT RADIUS TRAVELING LOOP (A-Loop)

VARIABLE RADIUS TRAVELING LOOP (B-Loop)

LATERAL OFFSET

ANGULAR DEFLECTION

VERTICAL LOOP WITH MOVEMENT IN TWO DIRECTIONS (Combination Loop)